CROP

It all starts with the cultivation of the seed of the Persicaria tinctoria variety in Santa María de las Lomas, Extremadura, Spain. At Tintoremus, we generate our own seed, manage all the plantations, and perform the various harvests. Once the plant is harvested, the leaves are transported to the extraction center to begin the pigment extraction process.

EXTRACTION PROCESS

FERMENTATION

Once we have cutted the plant, we place the indigo leaves in pools of water and keep them for a specific time and at a specific temperature to begin the fermentation process.

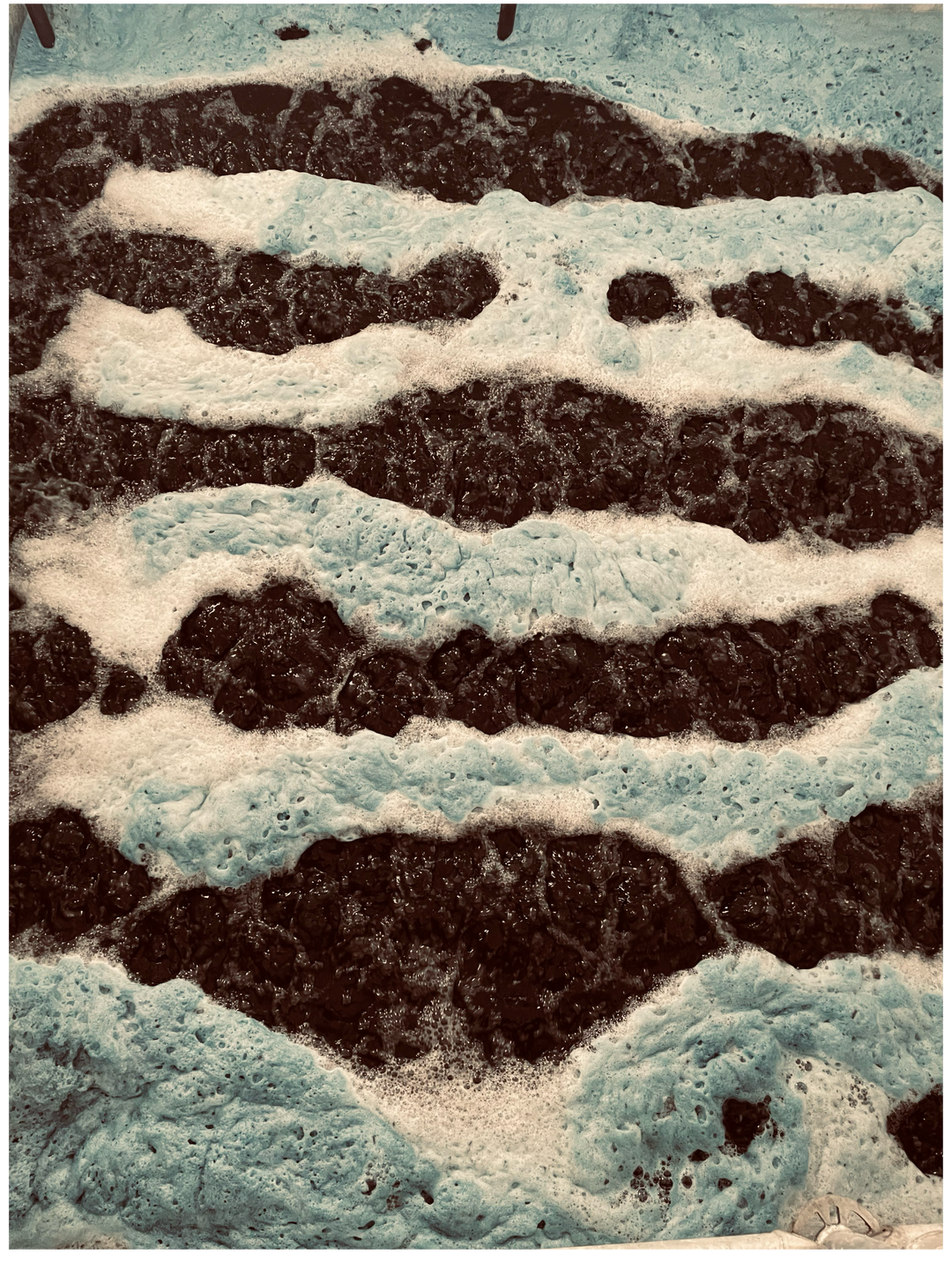

OXYGENATION

We remove the leaves from the fermentation pools, which become compost, and we transfer the "excess" water to our oxygenation pools. This is when we begin the process of oxygenating the fermented mixture.

FILTRATION

The mixture (now oxygenated) passes from the oxygenation pools to a filter press. The purpose of filtering is to retain the pigment and separate it from the excess water. After the entire process and a drying period, we obtain the final pigment.

Crop Analysis

We work hand to hand with Agrodato, with whom we carry out a precise diagnosis of the state of the crop and continuous monitoring through data processing.

Our meteorological station analyses temperature, wind, rainfall...

We also have sensors in the crop that measure the water we consume, humidity, soil temperature...

Our objective is to optimise each batch of pigment and promote traceability throughout the entire process.